Drill-Ream Actuator

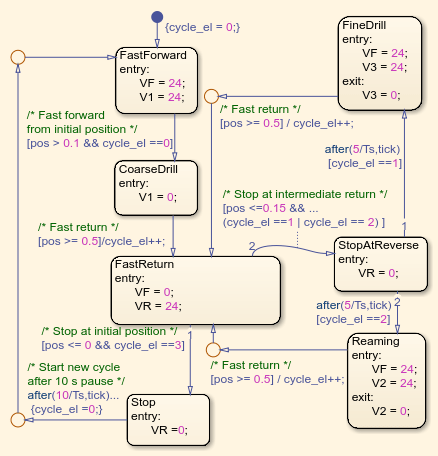

This example shows an actuator that drives a machine tool working unit performing a sequence of three technological operations: coarse drilling, fine drilling, and reaming. The actuator speed is controlled by one of three pressure-compensated flow control valves metering out return flow from the cylinder. The selection of an appropriate flow control is performed by directional valves that are activated by a control unit.

From the Valve Control, signals VF and VR are the signals that activate forward and return motions, respectively, by shifting the main directional valve. Signal V1 activates normally- closed valve Valve1 Retract. When opened, Valve1 Retract bypasses all flow controls and sets the fast traverse speed. V2 controls valve Valve2 Ream. When deenergized, this valve directs return flow through Flow Control Reaming, which is set to reaming speed. Signal V3 directs flow either through Flow Control Fine Drilling or Flow Control Coarse Drilling.

The load is simulated as a position-dependent force using a table lookup block.

Flow control valves are arranged as a subsystem comprised of a fixed orifice and a pressure compensator.

Model

Cycle Manifold Subsystem

Valve Control Subsystem

Simulation Results from Simscape Logging

The plots below show the pressures in the cylinder and the position of the piston. Three operating speeds are shown in the plots.

The plots below show the states of the different valves. Forward/Reverse has 3 states (Forward/Locked/Reverse), while the others have two states. Retract and Ream have states of on/off, and Fine/Coarse valve selects between two different flow restrictions.