Data Analysis and Feature Extraction for Battery Raw Cycling Data

This example shows the workflow of organizing and analyzing raw data from battery test cyclers. The example, using batteryTestDataParser and batteryTestFeatureExtractor, focuses on extracting critical features from the data to understand Lithium-ion Batteries (LIBs) behavior and prepare for AI-based health monitoring and management systems.

Battery Cell Data

The measurements from LIBs are collected during cycling tests under fast-charging conditions, using a 48-channel Arbin LBT potentiostat within a temperature-controlled chamber set at 30°C [1]. You can access the detailed description of the dataset here [2]. This example focuses a single cell that is cycled to failure (80% state of health) in order to provide a comprehensive view of its performance over time. The cycling sequence exercises the battery cell with dynamic fast charging and constant 4C discharging. The cell data includes essential measurements and per-cycle summaries:

Date Time: Recorded in date-time format, which may be reset during a cycle due to data collection errors.

Cycle Index: An integer identifying the cycle number.

Step Index: An integer identifying the steps within the fast-charging policy.

Current: Measured in amperes (A).

Voltage: Measured in volts (V).

Temperature: Measured in degrees Celsius (°C).

Load the battery cell data from the MathWorks support files site. To generalize across different battery cyclers, only the essential measurements specified above are utilized.

dataFile = matlab.internal.examples.downloadSupportFile("predmaint","batteryagingdata/singlecell/v1/singleCellLifeTimeData.zip"); unzip(dataFile) load("singleCellLifeTimeData.mat") head(data,5)

Data_Point Test_Time DateTime Step_Time Step_Index Cycle_Index Current Voltage Charge_Capacity Discharge_Capacity Charge_Energy Discharge_Energy dV/dt Internal_Resistance Temperature

__________ _________ ____________________ _________ __________ ___________ _______ _______ _______________ __________________ _____________ ________________ ___________ ___________________ ___________

1 0 13-May-2017 03:21:40 -1780 0 0 0 3.3018 0 0 0 0 -1.5259e-05 0.022012 30.457

2 0.0001 13-May-2017 03:21:40 -1780 0 0 0 3.3018 0 0 0 0 -1.5259e-05 0.022012 30.457

3 9.9983 13-May-2017 03:21:50 -1770 0 0 0 3.3018 0 0 0 0 -2.6703e-05 0.022012 30.445

4 20.002 13-May-2017 03:22:00 -1760 0 0 0 3.3018 0 0 0 0 -1.5259e-05 0.022012 30.501

5 30.001 13-May-2017 03:22:10 -1750 0 0 0 3.3018 0 0 0 0 -8.5831e-06 0.022012 30.501

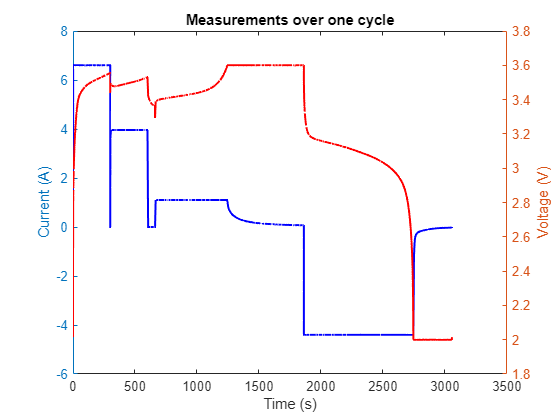

To understand the charging and discharging policy, visualize the current and voltage measurements for one cycle of the battery. In each cycle, the battery is fully charged until it reaches 3.6V and fully discharged when it reaches 2V.

cycleData = data(data.Cycle_Index == 1, :); cycleData.DateTime = seconds(cycleData.DateTime - cycleData.DateTime(1)); figure; yyaxis left; plot(cycleData.DateTime,cycleData.Current, '-b', 'LineWidth', 1.5); ylabel('Current (A)'); yyaxis right; plot(cycleData.DateTime,cycleData.Voltage, '-r', 'LineWidth', 1.5); ylabel('Voltage (V)'); xlabel("Time (s)"); title('Measurements over one cycle');

Data Exploration with batteryTestDataParser: Understand, Evaluate and Prepare the Data

1. Parse and segment data

To identify the cycling phases and modes and based on the measurements, use batteryTestDataParser. This function enables raw data visualization, aids in identifying anomalies, and prepare high-quality data. Properly understanding and preparing the input data ensures its suitability for meaningful feature extraction and in-depth analysis.

Create the parser object bparser to encapsulate the data and specify the properties that correspond to the names of the variables in the data.

bParser = batteryTestDataParser(data); bParser.CurrentVariable = 'Current'; bParser.VoltageVariable= "Voltage"; bParser.TimeVariable = "DateTime"; bParser.CycleIndexVariable = 'Cycle_Index'; bParser.StepIndexVariable = 'Step_Index';

Use segmentData to identify the cycling phase and mode that each data point belongs to, and flag invalid data points. If segmentData determines that a data point cannot be definitively assigned to a cycling phase or mode, the function marks the data point as invalid and excludes it from analysis and feature extraction. As a result, segmentData introduces three additional columns to the data in bparser: CyclingModes, CyclingPhases, and IsValid.

segmentedRawDataTable = segmentData(bParser); head(segmentedRawDataTable,5)

Data_Point Test_Time DateTime Step_Time Step_Index Cycle_Index Current Voltage Charge_Capacity Discharge_Capacity Charge_Energy Discharge_Energy dV/dt Internal_Resistance Temperature CyclingModes CyclingPhases IsValid

__________ _________ ____________________ _________ __________ ___________ _______ _______ _______________ __________________ _____________ ________________ ___________ ___________________ ___________ ____________ _____________ _______

1 0 13-May-2017 03:21:40 -1780 0 0 0 3.3018 0 0 0 0 -1.5259e-05 0.022012 30.457 Rest Rest true

2 0.0001 13-May-2017 03:21:40 -1780 0 0 0 3.3018 0 0 0 0 -1.5259e-05 0.022012 30.457 Rest Rest true

3 9.9983 13-May-2017 03:21:50 -1770 0 0 0 3.3018 0 0 0 0 -2.6703e-05 0.022012 30.445 Rest Rest true

4 20.002 13-May-2017 03:22:00 -1760 0 0 0 3.3018 0 0 0 0 -1.5259e-05 0.022012 30.501 Rest Rest true

5 30.001 13-May-2017 03:22:10 -1750 0 0 0 3.3018 0 0 0 0 -8.5831e-06 0.022012 30.501 Rest Rest true

Display the segmented data for chosen cycles, with each cycle divided into several segments. Each segment is associated with a specific cycling mode, denoted by a unique color.

cycleList = unique(segmentedRawDataTable(segmentedRawDataTable.IsValid, :).Cycle_Index);

maxCycle = max(cycleList);

cycleIndex =  1;

hPlotRawMeasurementsWithSegments(segmentedRawDataTable, bParser, cycleIndex)

1;

hPlotRawMeasurementsWithSegments(segmentedRawDataTable, bParser, cycleIndex)![Figure contains 2 axes objects and another object of type subplottext. Axes object 1 with xlabel Time [s], ylabel Voltage [V] contains 5 objects of type line. One or more of the lines displays its values using only markers These objects represent data, CC, CV, Rest, Undefined. Axes object 2 with xlabel Time [s], ylabel Current [A] contains 5 objects of type line. One or more of the lines displays its values using only markers These objects represent data, CC, CV, Rest, Undefined.](../../examples/predmaint/win64/BatteryCyclingDataFeatureExtractionExample_02.png)

2. Find abnormal data points

During the data collection process, time is expected to be recorded in a non-decreasing sequence with predefined time interval. However, unusually long intervals between data points might occur due to computer auto-restarts [1]. Extended periods between consecutive data points can potentially distort the temporal resolution of the dataset.

Define a long time interval as 3600 seconds. Identify any point-to-point time intervals within one cycle that exceed this duration, as they are considered abnormal.

longInterval = 3600; timeDiff = diff(seconds(segmentedRawDataTable.DateTime - segmentedRawDataTable.DateTime(1))); longIndex = find(timeDiff > longInterval)+1; fprintf("Data point %s have abnormally long time interval.", strjoin(string(longIndex), ', '))

Data point 848, 919050 have abnormally long time interval.

To understand the underlying reasons for these long time intervals, check raw data points before and after anomalies.

dataPoint =919050; segmentedRawDataTable(dataPoint-1:dataPoint+1,["Data_Point", "DateTime", "Step_Index", "Cycle_Index", "IsValid"])

ans=3×5 table

Data_Point DateTime Step_Index Cycle_Index IsValid

__________ ____________________ __________ ___________ _______

9.1905e+05 13-Jun-2017 08:10:00 11 876 false

9.1905e+05 14-Jun-2017 17:19:12 11 876 false

9.1905e+05 14-Jun-2017 17:19:12 11 876 false

To address the long interval, you can either 1) exclude the abnormal cycles/data points from the dataset, or 2) manually adjust the DateTime value. Selecting an approach requires thoroughly reviewing the data, such as visualizing the suspected cycles with segmentation or inspecting the raw data values. For this example, you can exclude entire cycle 0 which contains data point 848, since cycle 0 has different charging and discharging segments. The batteryTestDataParser has already identified data point 919050 as invalid, so it does not require further action.

3. Find abnormal cycles

From the segmented data plot in the previous step, you can observe that each segment corresponds to a specific cycling phase and mode. It is common for certain cycles to lack segments that are present in other cycles, resulting in altered or missing features. A normal cycle is defined as one that follows a pattern observed in more than 90% of the cycles. Cycles deviating from this norm, especially those missing steps that are present in the majority, are classified as abnormal. In the result table, a value of 1 indicates that the specified mode at the step is present in the cycle, while a value of 0 means the cycle lacks this step in the given mode.

The next step is to detect abnormal cycles. In this example, you can focus on the discharging phase as the data has varying charging profiles and a consistent discharging profile. The detection result indicates the cycle 642, 744, and 750 miss step 10 in both CC (constant current) and CV (constant voltage) modes. You can exclude these cycles in the feature extraction.

dischargeData = segmentedRawDataTable(segmentedRawDataTable.IsValid & (segmentedRawDataTable.CyclingPhases == "Discharge") ... & (segmentedRawDataTable.CyclingModes == "CC" |segmentedRawDataTable.CyclingModes == "CV"), :); MissingStepTable = hDetectMissingStepCycles(dischargeData,bParser.CycleIndexVariable, bParser.StepIndexVariable, "CyclingModes"); MissingStepTable

MissingStepTable=3×3 table

Cycle_Index step 10 mode CC step 10 mode CV

___________ _______________ _______________

642 0 0

744 0 0

759 0 0

Feature Extraction with batteryTestFeatureExtractor: Provide insights of battery health status

1. Extract features from preprocessed data

After identifying the abnormal data points and cycles, update ExcludedCycles property accordingly.

bParser.ExcludedCycles = [0,642,744,759];

Use batteryTestFeatureExtractor to specify the options in feature extraction. This example focuses on discharging phase and enables incremental capacity (IC) and differential voltage (DV) analysis. Then, use extract to internally calculate differential curves and extract a comprehensive set of features from the segmented data and calculated curves.

extractor = batteryTestFeatureExtractor();

extractor.CyclingPhase = 'Discharge';

extractor.IC = true;

extractor.DV = true;

featureTable = extract(extractor, bParser);

head(featureTable, 5) Cycle_Index Discharge_cumulativeCapacity Discharge_cumulativeEnergy Discharge_duration Discharge_startVoltage Discharge_Voltage_max Discharge_Voltage_min Discharge_Voltage_mean Discharge_Voltage_std Discharge_Voltage_skewness Discharge_Voltage_kurtosis Discharge_Current_max Discharge_Current_min Discharge_Current_mean Discharge_Current_std Discharge_Current_skewness Discharge_Current_kurtosis Discharge_Step10_IC_peak Discharge_Step10_IC_peakWidth Discharge_Step10_IC_peakLocation Discharge_Step10_IC_peakProminence Discharge_Step10_IC_peaksArea Discharge_Step10_IC_peakLeftSlope Discharge_Step10_IC_peakRightSlope Discharge_Step10_IC_area Discharge_Step10_IC_max Discharge_Step10_IC_min Discharge_Step10_IC_mean Discharge_Step10_IC_std Discharge_Step10_IC_skewness Discharge_Step10_IC_kurtosis Discharge_Step10_DV_peak Discharge_Step10_DV_peakWidth Discharge_Step10_DV_peakLocation Discharge_Step10_DV_peakProminence Discharge_Step10_DV_peaksArea Discharge_Step10_DV_peakLeftSlope Discharge_Step10_DV_peakRightSlope Discharge_Step10_DV_area Discharge_Step10_DV_max Discharge_Step10_DV_min Discharge_Step10_DV_mean Discharge_Step10_DV_std Discharge_Step10_DV_skewness Discharge_Step10_DV_kurtosis Discharge_Step10_CC_duration Discharge_Step10_CC_currentMedian Discharge_Step10_CC_slope Discharge_Step10_CC_energy Discharge_Step10_CC_skewness Discharge_Step10_CC_kurtosis Discharge_Step10_CC_tInv Discharge_Step10_CV_duration Discharge_Step10_CV_voltageMedian Discharge_Step10_CV_slope Discharge_Step10_CV_energy Discharge_Step10_CV_skewness Discharge_Step10_CV_kurtosis Discharge_Step10_CCCV_energyRatio Discharge_Step10_CCCV_energyDifference

___________ ____________________________ __________________________ __________________ ______________________ _____________________ _____________________ ______________________ _____________________ __________________________ __________________________ _____________________ _____________________ ______________________ _____________________ __________________________ __________________________ ________________________ _____________________________ ________________________________ __________________________________ _____________________________ _________________________________ __________________________________ ________________________ _______________________ _______________________ ________________________ _______________________ ____________________________ ____________________________ ________________________ _____________________________ ________________________________ __________________________________ _____________________________ _________________________________ __________________________________ ________________________ _______________________ _______________________ ________________________ _______________________ ____________________________ ____________________________ ____________________________ _________________________________ _________________________ __________________________ ____________________________ ____________________________ ________________________ ____________________________ _________________________________ _________________________ __________________________ ____________________________ ____________________________ _________________________________ ______________________________________

1 1.0858 3.3053 1186.2 3.3297 3.3297 1.9996 2.7518 0.46306 -0.69494 1.7957 -0.021996 -4.4004 -3.6203 1.6577 1.6544 3.741 6.7975 0.11988 3.1491 6.6874 0.53131 40.006 -124.84 1.0703 6.7975 -0.014311 0.80703 1.5432 2.3837 7.7647 0.57015 5.0015 712.65 0.012363 2.2763 0.0017713 -0.0023938 1031 71.209 0.13451 1.2225 4.7706 9.9536 120.4 875.8 -4.4 0.00030465 3.2745 -1.363 3.6784 760.95 300.43 1.9999 0.00093293 0.016935 -2.3131 9.8519 193.36 3.2575

2 1.0876 3.3111 1191.7 3.3199 3.3199 1.9996 2.7293 0.46952 -0.62182 1.679 -0.022033 -4.4006 -3.5379 1.7243 1.4985 3.249 6.7984 0.11951 3.1457 6.6764 0.54736 38.573 -127.79 1.0721 6.7984 -0.019335 0.81345 1.5523 2.374 7.7118 0.59732 2.382 718.26 0.0028934 1.1938 0.0019541 -0.00051788 1025.2 70.425 0.13238 1.2129 4.7303 9.9126 119.42 877.32 -4.4 0.00030269 3.2804 -1.3602 3.6885 761.05 304.33 1.9999 0.00088585 0.016846 -2.3857 10.332 194.73 3.2635

3 1.0972 3.3433 1198.5 3.4424 3.4424 1.9996 2.7497 0.47889 -0.6258 1.7303 -0.022201 -4.4005 -3.5499 1.7126 1.5172 3.3065 6.7829 0.12166 3.1522 6.7482 0.53042 40.973 -120.47 1.0818 6.7829 -0.021383 0.75001 1.5018 2.5311 8.5461 0.53079 4.1924 708.15 0.022543 2.107 0.0072674 -0.0034486 1119.2 70.355 0.13308 1.315 4.8527 9.1793 106.04 885.19 -4.4 0.00030422 3.3127 -1.3307 3.7906 760.88 303.26 1.9999 0.00094755 0.016758 -2.4133 9.9184 197.68 3.296

4 1.097 3.3423 1197.7 3.4182 3.4182 1.9996 2.735 0.481 -0.57359 1.6517 -0.022873 -4.4004 -3.5176 1.739 1.4618 3.1404 6.7829 0.121 3.1502 6.7368 0.53385 41.007 -125.91 1.0815 6.7829 -0.0073165 0.76354 1.5115 2.4976 8.3636 0.73393 3.2183 750.81 0.014997 1.4667 0.00051992 -0.0050005 1100.9 69.473 0.12486 1.2924 4.7698 9.2975 108.3 884.95 -4.4 0.00029715 3.3115 -1.2773 3.5595 765.91 302.74 2 0.00085562 0.016897 -2.5036 11.241 195.99 3.2946

5 1.0899 3.3189 1191.5 3.319 3.319 1.9957 2.7191 0.47534 -0.57212 1.6031 -0.022711 -4.4004 -3.5032 1.7484 1.4358 3.0653 6.7769 0.12188 3.1521 6.6506 0.5366 40.214 -122.29 1.0744 6.7769 -0.013659 0.81197 1.5549 2.3806 7.7339 0.59341 3.509 718.11 0.012226 1.1844 0.0048458 -0.0003461 1030 70.095 0.1361 1.2156 4.7284 9.8499 118.04 879.13 -4.4 0.00030022 3.2881 -1.3286 3.5449 760.85 302.39 1.9999 0.00089706 0.017049 -2.309 9.7528 192.86 3.271

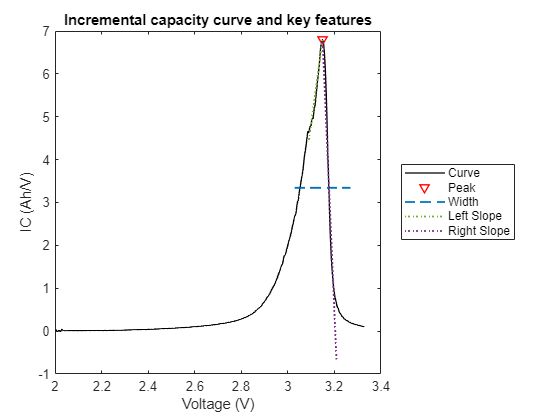

2. Analyze differential curve related features

As a non-destructive technique for characterizing LIBs, differential curve analysis has been widely used to identify aging mechanisms. To investigate the LIBs' capacity degradation mechanism, use computeDifferentialCurves to calculate the differential curves and then visualize the curve. Plot a set of curve-related features such as peak location, height and slope along with the curve.

differentialTable = computeDifferentialCurves(bParser); stepIndex = 10; cycleIndex =1; curveType =

'IC'; hPlotCurveWithFeature(featureTable, differentialTable, bParser, cycleIndex, stepIndex, curveType)

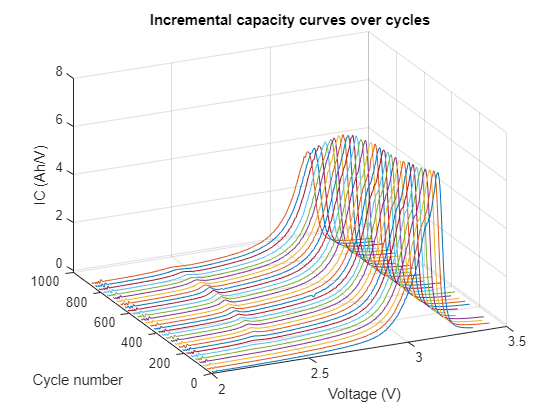

The evolution of the IC curves over the battery lifetime associates with the capacity loss of the LIB. In order to gain valuable insights from the curves, it is critical to identify the key features associated with battery degradation. One method to accomplish this is to plot incremental capacity curves across cycles.

cycleList = sort(unique(differentialTable.(bParser.CycleIndexVariable)));

cyclingPhase = "Discharge";

stepIndex = 10;

plotInterval = 30;

hPlotCurvesforCycles(differentialTable, bParser, cycleList, cyclingPhase, stepIndex, plotInterval, curveType)

This plot illuminates the degradation patterns of LIBs, allowing for a clearer understanding of how certain features evolve as the battery ages.

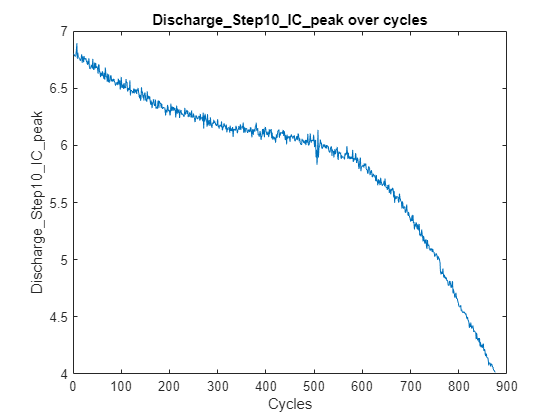

A notable observation is the decrease of peak height and peak area of the IC curve over time, which is a key indicator of battery degradation. Another significant observation is the shift of DV curve peak location across cycles, which provides insights of the changing health status.

Based on the observations, you can identify the features that are more relevant to battery degradation, such as peak height, peak location, and peak area, which decrease as the cycle number increases.

featureName =  "Discharge_Step10_IC_peak";

hPlotFeatureOverCycles(featureTable,featureName, bParser.CycleIndexVariable);

"Discharge_Step10_IC_peak";

hPlotFeatureOverCycles(featureTable,featureName, bParser.CycleIndexVariable);

3. Analyze general features

With the increase in internal resistance and loss of capacity caused by repeated charging and discharging, the time for a battery to reach terminal voltage during charging and discharging can be gradually shortened. Measurements also fluctuate over time. Therefore, in addition to curve-related features, you can extract a wide array of other features, including statistical metrics, domain-specific characteristics, and features specific to different cycling modes.

Visualizing these features over time helps to understand the feature trajectory. Features such as Discharge_Step10_CCCV_energyRatio, Discharge_Step10_CCCV_energyDifference, Discharge_Step10_CC_duration, Discharge_Voltage_mean, show significant changes of the trend over cycles. As expected, the duration of the CC mode decreases as battery capacity degrades, since the battery reaches terminal voltage earlier. This early termination of the CC mode also results in a lower average voltage and decreased CC energy. Consequently, the energy difference and ratio between CC and CV modes degrade over time.

featureNameList = ["Discharge_Step10_CCCV_energyRatio", "Discharge_Step10_CCCV_energyDifference", "Discharge_Step10_CC_duration", "Discharge_Voltage_mean"]; hPlotFeaturesTiles(featureTable, featureNameList, bParser.CycleIndexVariable)

Conclusion

This example provides a comprehensive guide on using batteryTestDataParser and batteryTestFeatureExtractor for effective data preparation, data analysis and feature extraction from battery data. The workflow includes:

Ingesting raw data from battery cyclers and converting it into a standardized format for analysis;

Identifying data anomalies that may affect analysis accuracy;

Evaluating the data and features through extensive visualization;

Gaining deeper insights into battery performance through the analysis of differential curves and extracted features.

The next step involves employing feature selection algorithms to automate the identification of relevant features. These selected features can then be utilized to train machine learning or deep learning models for various applications within the battery predictive maintenance domain.

References

[1] Severson, K.A., Attia, P.M., Jin, N. et al. "Data-driven prediction of battery cycle life before capacity degradation." Nat Energy 4, 383–391 (2019). https://doi.org/10.1038/s41560-019-0356-8

See Also

batteryTestFeatureExtractor | batteryTestDataParser | extract | computeDifferentialCurves | segmentData