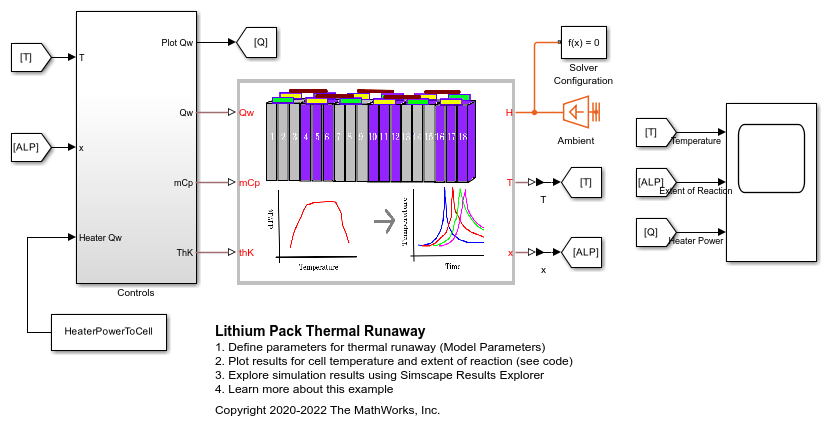

Lithium Pack Thermal Runaway

This example shows how to model a thermal runaway in a lithium-ion battery pack. The model measures the cell heat generation, the cell-to-cell heat cascade, and the subsequent temperature rise in the cells, based on the design. The cell thermal runaway abuse heat is calculated using calorimeter data. Simulation is run to evaluate the number of cells that go into runaway mode, when just one cell is abused. To delay or cancel the cell-to-cell thermal cascading, this example models a thermal barrier between the cells.

Model Overview

The example models a battery pack that consists of eight pouch-shaped lithium-ion cells. The cells are in contact with each other. An external heater abuses the first cell. The heater heats the first cell enough to start the thermal runaway reaction. During the abuse period, the model uses the calorimeter data to estimate the cell self-heat generation and simulates the time needed by the other cells to go into their own respective runaway reactions. To stop the thermal cascading, this example models a thermal barrier between cell 4 and cell 5. Then, it calculates the thickness of this barrier to prevent the fifth cell to go into thermal runaway. These are the parameters in the battery pack:

Temperature (T) vector over which dT/dt is tabulated, T - Temperature values at which the derivative of the temperature with time is defined, specified as an array of scalars. This data is typically obtained from a calorimeter test on a single lithium-ion cell.

Rate of temperature change (dT/dt) vector, dT/dt - Derivative of the temperature with time, specified as an array of scalars of the same size of the Temperature (T) vector over which dT/dt is tabulated, T parameter. This data is typically obtained from a calorimeter test on a single lithium-ion cell.

Heat of abuse reaction - Heat of the chemical reaction modeled using calorimetry data, specified as a scalar.

Active reactant mass as a fraction of cell mass - Mass of the reactant or the active material used in the thermal abuse reaction, specified as a fraction greater than

0. The value of this fraction is equal to the mass of the reactant divided by the total mass of the cell.

Number of cells in stack - Number of cells in the battery pack, specified as an integer greater than one.

Cell height - Cell height, specified as a positive scalar.

Cell width - Cell width, specified as a positive scalar.

Cell thickness - Cell thickness, specified as a positive scalar.

Cell density - Cell density, specified as a positive scalar.

Cell specific heat - Cell specific heat, specified as a positive scalar.

Heat transfer coefficient to ambient - Cell heat transfer coefficient, specified as a positive scalar.

Cell thermal conductivity - Cell through-plane thermal conductivity value, specified as a positive scalar.

Cell initial temperature vector - Cell initial temperature, specified as a vector. The number of elements in this vector must be equal to the value of the Number of cells in stack parameter.

Cell-to-cell gap length vector - Distance between the individual cells, specified as a vector. The number of elements in this vector must be equal to the value of the Number of cells in stack parameter - 1.

Cell-to-cell gap thermal mass vector - Thermal mass of the material in the gap between each cell, specified as a vector. The number of elements in this vector must be equal to the value of the Number of cells in stack parameter - 1.

Cell-to-cell gap thermal conductivity vector - Thermal conductivity of the material in the gap between each cell, specified as a vector. The number of elements in this vector must be equal to the value of the Number of cells in stack parameter - 1.

To define the external heat input, the thermal mass change, and the thermal conductivity of each cell, specify these inputs:

Qw - External heat input to each cell, specified as a vector of scalars.

mCp - Thermal mass change of each cell, specified as a fraction greater than 0. To obtain the actual thermal mass of the cell, this value is multiplied to the cell thermal mass. The mCp port value models the changes in the cell thermal mass as the cell reacts. In this example, the mCp port value does not change with time or cell reaction.

thK - Thermal conductivity change of each cell, specified as a fraction greater than 0. To obtain the actual thermal conductivity of the cell, this value is multiplied to the Cell thermal conductivity parameter. The thK port value models the changes in the cell thermal conductivity due to the gases being vented out and the cell becoming hollow. In this example, the thK port value does not change with time or cell reaction.

To access cell temperature output and extent of reaction, use these two outputs:

T - Temperature of all the cells in the battery pack, specified as a vector of scalar.

x - Extent of reaction for all the cells in the battery pack, specified as a vector of scalar.

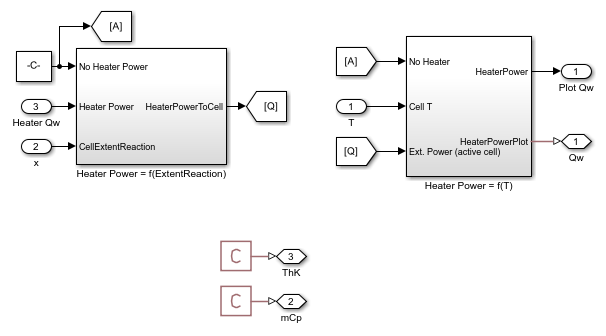

Controls Overview

The Controls subsystem manages the heater operations. The heater provides a constant power to the first cell in the module, equal to the value of the HeaterPowerToCell workspace variable in the LithiumPackThermalRunawayINI.m file. The Heater Power = f(ExtentReaction) and Heater Power = f(T) blocks in the Controls subsystem check for the heater power input based on the measurements of the cell temperature. If the cell temperature is greater than the temperature cut-off limit, specified by the stopHeaterWhenTempAbove workspace variable, the heater switches off.

Simulation Results

The workspace variables in the LithiumPackThermalRunawayINI.m file set all the parameters and inputs. The initial temperature of all cells is 300 K and the stopHeaterWhenTempAbove workspace variable is equal to 443 K. The heater provides a constant power equal to 500 W to the first cell. When the cell temperature reaches the value specified in the stopHeaterWhenTempAbove, the heater switches off. Then, the cell- to-cell thermal cascading process begins. The first cell experiences a thermal runaway reaction, followed by all subsequent cells. The heat that you must remove from the battery pack is directly proportional to the number of cells that experience a runaway reaction. In this example, the battery pack can safely contain a total thermal energy equal to the thermal energies of four cells. To slow down or stop the cascading and prevent the damage of the cells, you must add thermal barriers between the cells. This example models a thermal barrier between the fourth and fifth cell. The Cell-to-cell gap parameter models the characteristics of the thermal barrier. You can edit this parameter by specifying these workspace variables in the LithiumPackThermalRunawayINI.m file:

cellToCellGapLen(1,4) is equal to 0.005, or 5 millimeters.

cellToCellGapThermalMass(1,4) is equal to 50 J/K.

cellToCellGapThermalK(1,4) is equal to 0.05 W/m*K.

With these specifications, the thermal runaway stops at the fourth cell. The fifth, sixth, seventh, and eighth cells do not experience a thermal runaway. The results show how a 5 millimeters thermal barrier is enough to manage the spread of heat due to thermal cascading and runaway reactions.

Simulation Results Without Thermal Barrier

These plots show the cell temperature rise and thermal runaway in all the cells of the pack when there is no thermal barrier between the fourth and fifth cells.