EtherCAT Protocol Sequenced Writing CoE Subordinate Device Configuration Variables

This example shows how to use CoE blocks and a simple state machine to write configuration values to variables that can only be written before going to EtherCAT® Op state. For code needed to use the SoE blocks for subordinate devices that understand SoE protocol, see EtherCAT Protocol Sequenced Writing SoE Subordinate Device Configuration Variables.

For subordinate devices that understand CoE addressing, limited ability to read or write specific objects is somewhat rare. For subordinate devices that understand SoE addressing, this restriction is much more common.

This example also shows distributed clocks synchronization using the bus shift DC mode where the subordinate devices are shifted in time to match the execution time of the main device.

Requirements

To run this example, you need an EtherCAT network that consists of the target computer as EtherCAT main device and at least one subordinate device that has CoE addressed objects. The supplied ENI file is for a 5 element subordinate device stack: EK1100+EL1202+EL2202+EL3102+EL4032.

EtherCAT in Simulink® Real-Time™ requires a dedicated network port on the target computer that is reserved for EtherCAT by using the Ethernet configuration tool. Configure the dedicated port for EtherCAT communication, not with an IP address. The dedicated port must be distinct from the port used for the Ethernet link between the development and target computers.

To test this model:

Connect the port that is reserved for EtherCAT in the target computer to the EtherCAT IN port of the EL1100 interface.

Make sure the EK1100 is supplied with a 24-volt power source.

Build and download the model onto the target.

For a complete example that configures the EtherCAT network, configures the EtherCAT main device node model, and builds then runs the real-time application, see Modeling EtherCAT Networks.

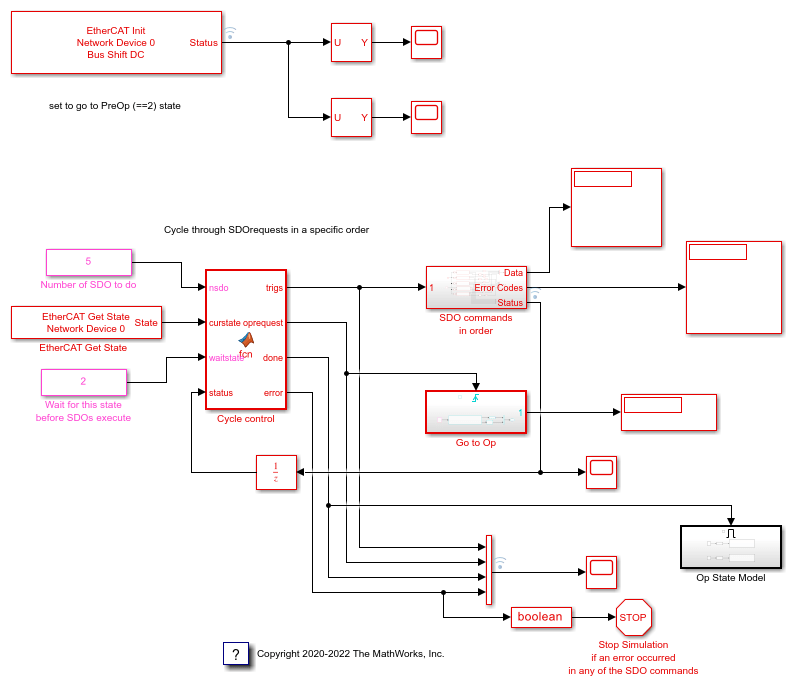

Open the Model

This model illustrates how you can read or write to CoE/SDO objects if they are only writable in EtherCAT PreOp state. You can move the CoE/SDO transfers to EtherCAT SafeOp state by changing the Initialization end state in the EtherCAT Init block and by also changing the constant in the Wait for this state constant block. These settings direct the state machine to start sending CoE messages when it reaches the initialization end state.

Init = 1

PreOp = 2

SafeOp = 4

Op = 8

The EtherCAT initialization block requires that the configuration ENI file is present in the current folder.

If you want to modify this model to experiment with it, then copy the example configuration file from the example folder to the current folder. To open the model, in the MATLAB® Command Window, type:

model = 'slrt_ex_ethercat_asyncCoE_cycle';

open_system(model)

Figure 1: EtherCAT model for sequencing through CoE commands after pausing initialization at PreOp state

Configure the Model

Open the parameter dialog for the EtherCAT Init block and observe the pre-configured values. The EtherCAT subordinate devices that are daisy chained together with Ethernet cable is a Device, also referred to as an EtherCAT network. The Device Index selects one such chained EtherCAT network. The Ethernet Port Number identifies which Ethernet port to use to access that Device. The EtherCAT Init block connects these two so that other EtherCAT blocks use the Device Index to communicate with the subordinate devices on that EtherCAT network.

If you only have one connected network of EtherCAT subordinate devices, and you have only reserved one Ethernet port with the Ethernet configuration tool, use Device Index = 0 and Ethernet Port Number = 1.

Create an ENI File for a Different Set of Subordinate Devices

If you need to create a new ENI file you need to use a third-party EtherCAT configurator such as TwinCAT 3 from Beckhoff® that you install on a development computer. The EtherCAT configuration (ENI) file preconfigured for this model is Stack4_BS_1ms.xml.

Each ENI file is specific to the exact network setup from which it was created (for example, the network discovered in step 1 of the configuration file creation process). The configuration file provided for this example is valid if and only if the EtherCAT network consists of an EK1100+EL1202+EL2202+EL3102+EL4032. If you have a different set of EtherCAT subordinate devices this example works, but you need to create a new ENI file that uses your devices.

For overview of the process for creating an ENI file, see Configure EtherCAT Network by Using TwinCAT 3.

If you use different subordinate devices, you need to consult the manual for your devices and find the CoE mapping. Using that mapping, you need to change the SDO commands in the SDO commands in order subsystem to use objects on your devices.

Build, Download, and Run the Model

To build, download, and run the model:

In the Simulink Editor, from the targets list on the Real-Time tab, select the target computer on which to run the real-time application.

Click Run on Target.

If you open the two host side scopes by double clicking each, data is relayed from the target computer to the development computer and is displayed.

Included in the model is the ability to control the amplitude of the cycling motion. With the Run on Target button, the slider is active and connected to the Amplitude constant block.

The model is preconfigured to run for 15 seconds. If you want to run the model longer, pull down the Run on Target menu and change the number on the bottom line. Press the green arrow to configure, build, and run.

Display the Target Computer Data

If you run the model using the Run on Target button, external mode is connected and you can double click the scope blocks and see the data on the development computer. The Display blocks also work.

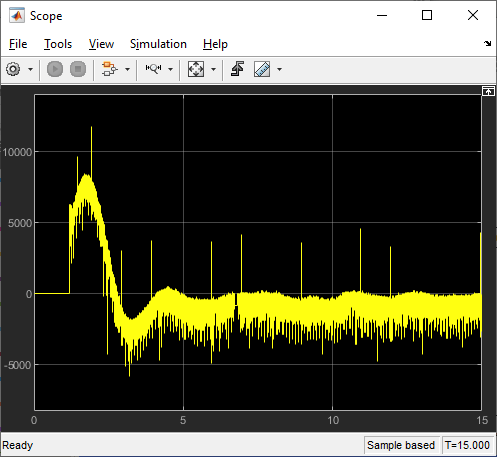

When using Run on Target, the Scope block shows the DC timing error between the main device code on the target computer and the first DC enabled subordinate device. Because the error is returned as nanoseconds, this graph shows that the timing difference settles down to the order of 3-5 microseconds (3000 to 5000 nanoseconds) difference between the DC enabled subordinate devices and the target machine running the code. The residual scatter reflects task scheduling variability in the target computer RTOS.

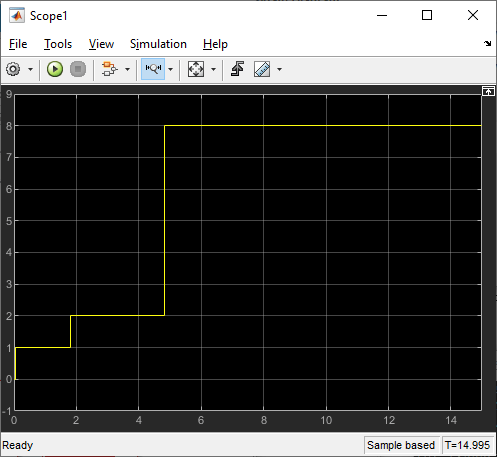

Scope1 shows the progression of EtherCAT states, from idle to Init to PreOp, SafeOp and finally Op state. SafeOp is only entered briefly and only shows up as the value 4 for a few time steps before the switch to Op state. Since this model uses the distributed clocks mechanism, the switch to Op state only occurs once the timing error settles down.

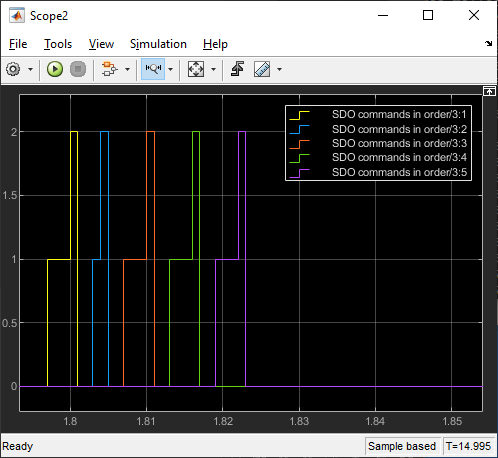

Scope2 shows the status outputs of the 5 async SDO blocks inside the subsystem. Each SDO block is enabled to write for one time step, then switches to status = 1 (busy) for a few time steps, then on successful completion status = 2 (done) for one time step. If a block encounters an error, status = 3 (error) for one time step. On an error, the Cycle control embedded MATLAB code block stops the sequence and sets the error output which stops the model. In that case, the failing block has output an error code that is displayed on Display1. This display is zoomed into the interval just after state went to PreOp (=2) state.

Scope3 shows several of the outputs from the Cycle control block. The first 5 are the enable signals, made true one at a time by Cycle control. Then the oprequest output is true for one time step to trigger the request to proceed to Op state. This display is zoomed in to the same interval as in Scope2.

When the requested SDO commands are complete and the state has progressed to Op state, the done signal is set to true for the remainder of execution. The rest of your model goes into the Op State Model subsystem.

If you need a different number of SDO commands to execute before Op state, you need to edit the Cycle control embedded MATLAB code block and modify the persistent array that is currently sized to have length 5, the same as the number of SDO commands being requesting.

If you run the model from the command line, you can use the Simulation Data Inspector to view any signal that has been marked for signal logging. Signals marked for signal logging have a dot with two arcs above it in the model editor.

See Also

bdclose(model);