looptune

Tune fixed-structure feedback loops

Syntax

Description

[

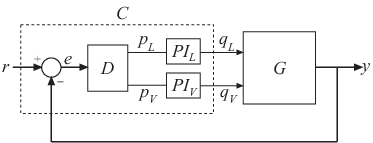

tunes the feedback loopG,C,gam]

= looptune(G0,C0,wc)

to meet the following default requirements:

Bandwidth — Gain crossover for each loop falls in the frequency interval

wcPerformance — Integral action at frequencies below

wcRobustness — Adequate stability margins and gain roll-off at frequencies above

wc

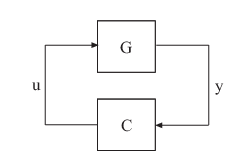

The tunable genss model

C0 specifies the controller structure, parameters, and

initial values. The model G0 specifies the plant.

G0 can be a Numeric LTI model, or,

for co-tuning the plant and controller, a tunable genss model. The sensor signals

y (measurements) and actuator signals u

(controls) define the boundary between plant and controller.

Note

For tuning Simulink® models with looptune, use slTuner (Simulink Control Design) to create an

interface to your Simulink model. You can then tune the control system with looptune (Simulink Control Design) for

slTuner (requires Simulink

Control Design™).

[

tunes the feedback loop to meet additional design requirements specified in one or

more tuning goal objects G,C,gam]

= looptune(G0,C0,wc,Req1,...,ReqN)Req1,...,ReqN. Omit

wc to use the requirements specified in

Req1,...,ReqN instead of an explicit target crossover

frequency and the default performance and robustness requirements.

Examples

Input Arguments

Output Arguments

Algorithms

looptune automatically converts target bandwidth, performance

requirements, and additional design requirements into weighting functions that express

the requirements as an H∞ optimization

problem. looptune then uses systune to optimize tunable parameters to minimize the

H∞ norm. For more information

about the optimization algorithms, see [1].

looptune computes the

H∞ norm using the algorithm of

[2] and structure-preserving eigensolvers from the SLICOT library. For more information

about the SLICOT library, see https://github.com/SLICOT.

Alternatives

For tuning Simulink models with looptune, see slTuner (Simulink Control Design) and looptune (Simulink Control Design) (requires Simulink

Control Design).

References

[1] P. Apkarian and D. Noll, "Nonsmooth H-infinity Synthesis." IEEE Transactions on Automatic Control, Vol. 51, Number 1, 2006, pp. 71–86.

[2] Bruinsma, N.A., and M. Steinbuch. "A Fast Algorithm to Compute the H∞ Norm of a Transfer Function Matrix." Systems & Control Letters, 14, no.4 (April 1990): 287–93.

Extended Capabilities

Version History

Introduced in R2011bSee Also

TuningGoal.Tracking | slTuner (Simulink Control Design) | systune | looptune (for slTuner) (Simulink Control Design) | TuningGoal.Gain | TuningGoal.LoopShape | hinfstruct (Robust Control Toolbox) | looptuneOptions | loopview | diskmargin (Robust Control Toolbox) | genss | connect