Simscape Multibody (precedentemente SimMechanics) offre un ambiente di simulazione multibody per sistemi meccanici 3D, come i robot, le sospensioni dei veicoli, le apparecchiature per l’edilizia e i carrelli di atterraggio per aeromobili. È possibile modellare sistemi multibody usando blocchi che rappresentano corpi, elementi di collegamento e di forza, vincoli e sensori. Simscape Multibody formula e risolve equazioni di moto per l’intero sistema meccanico. È possibile importare assemblaggi CAD completi nel proprio modello, comprese tutte le masse, le inerzie, gli elementi di collegamento, i vincoli e la geometria 3D. Un’animazione 3D generata in automatico ti consentirà di visualizzare la dinamica del sistema.

Simscape Multibody consente di sviluppare sistemi di controllo e di testare le prestazioni a livello di sistema. Sarà possibile parametrizzare i propri modelli utilizzando variabili ed espressioni MATLAB, oltre a poter progettare sistemi di controllo per il sistema multibody in Simulink. Sarà possibile integrare impianti elettrici, idraulici, pneumatici e altri sistemi fisici nel proprio modello usando componenti della famiglia di prodotti Simscape. Simscape Multibody supporta la generazione di codice C per distribuire i modelli in altri ambienti di simulazione, tra cui i sistemi Hardware-In-the-Loop (HIL).

Simulazione di meccanismi 3D

Crea modelli multibody di un qualunque meccanismo 3D. Definisci le parti usando la geometria 3D parametrizzata o i dati CAD. Collega le parti con elementi di giunzione per stabilire i gradi di libertà.

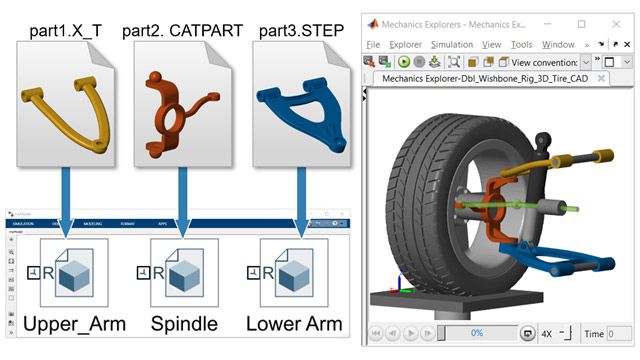

Importazione di CAD

Converti automaticamente dei progetti CAD per creare un gemello digitale del tuo sistema. Fai direttamente riferimento a file provenienti da CATIA®, Creo™, Inventor®, NX™, Solid Edge®, SolidWorks® e Parasolid®

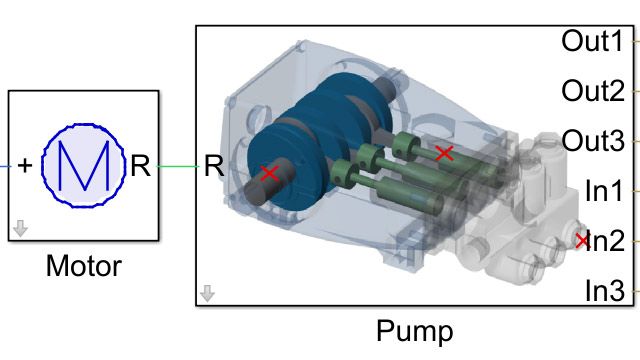

Azionamento elettrico e idraulico

Collega gli impianti elettronici, idraulici, pneumatici e altri tipi di sistemi direttamente al tuo modello meccanico 3D. Valuta la tecnologia dell’attuatore per verificarne la conformità ai requisiti prestazionali.

Forze di contatto

Modella il contatto intermittente e persistente tra modelli parametrici e solidi definiti nel software CAD. Definisci leggi delle forze personalizzate. Usa dei modelli di penumatici per il contatto strada/veicolo.

Corpi flessibili

Modella dei corpi flessibili servendoti di metodi di modellazione degli elementi finiti e teorici. Varia le proprietà con MATLAB per analizzare l’effetto di fenomeni quali l’estensione, la flessione e la torsione sul sistema.

Progettazione parametrica

Usa MATLAB per variare i parametri di progettazione quali la lunghezza, la massa e la tensione. Usa la simulazione dinamica con modelli astratti per completare i progetti meccanici con un numero inferiore di iterazioni.

Distribuzione dei modelli

Converti il tuo modello Simscape in codice C per testare algoritmi di controllo. Esegui test HIL su dSPACE®, Speedgoat, OPAL-RT e altri sistemi in tempo reale prima di eseguire test fisici.

MATLAB e Simulink

Usa MATLAB per automatizzare le attività quali l’assemblaggio del modello, il testing e la post-elaborazione. Usa Simulink per integrare gli algoritmi di controllo e le progettazioni hardware in un unico ambiente.

Dalla ricerca alla produzione

I modelli Simscape aiutano ad affinare i requisiti, a progettare i sistemi di controllo, a testare i controller embedded e a supportare il funzionamento in servizio come gemello digitale.

Risorse sui prodotti:

Famiglia di prodotti Simscape

La famiglia di prodotti Simscape fornisce modelli e tecnologie di risoluzione per la simulazione di sistemi fisici. Modella sistemi elettrici, meccanici, fluidi e altri sistemi fisici assemblando i componenti in uno schema.

Simscape

Modellazione e simulazione di sistemi fisici multidominio

Simscape Electrical

Modellazione e simulazione di sistemi elettronici, meccatronici e di alimentazione elettrica

Simscape Battery

Progettazione e simulazione di sistemi di accumulo dell’energia e di batterie

Simscape Fluids

Modellazione e simulazione di sistemi fluidodinamici

Simscape Driveline

Modellazione e simulazione di sistemi meccanici rotazionali e traslazionali

Simscape Multibody

Modellazione e simulazione di sistemi meccanici multibody

“Simulink, Simscape Multibody e Simulink Coder ci hanno permesso di passare in autonomia da un modello CAD accurato del veicolo MRO al codice C eseguito in tempo reale.”

Jim Chapel, Lockheed Martin Space Systems

Richiedi una versione di prova gratuita

30 giorni di prova a tua disposizione.

Pronto per acquistare?

Richiedi una quotazione e scopri i prodotti correlati.

Sei uno studente?

È possibile che la tua scuola già fornisca accesso a MATLAB, Simulink e ad altri prodotti complementari mediante una Campus-Wide License.